……by Ben Ndubuwa……..

Major Energy Marketers Association of Nigeria (MEMAN) has said that governments worldwide are responsible for setting and enforcing fuel standards and specifications, which vary across regions. While some countries maintain standards exclusively for petrol and ethanol, others extend regulations to petrol-ethanol blends. The protocols for establishing these standards typically fall into three categories: adopting international standards, customizing standards to fit national needs or a hybrid of both approaches.

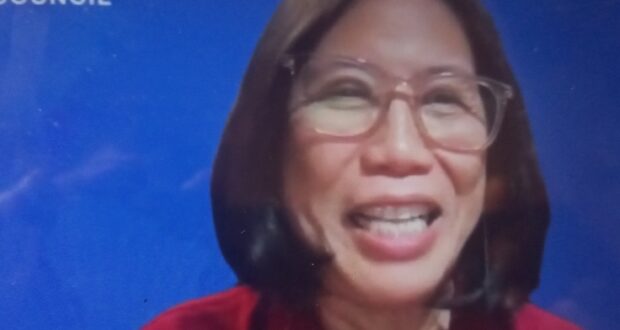

Speaking at a one-day stakeholders forum organized by MEMAN Competence Centre Series in conjunction with an official of U.S, Grain, Mrs Rowena Torres-Ordonee in her presentation titled “Fuel Standards and Specifications: Allowing a Role for Ethanol” said that Ethanol has one prominent international standard-setting body which is ASTM International, formerly known as the American Society for Testing and Materials.

Torree-Ordonee said that ASTM develops and publishes technical standards through consensus, covering a broad spectrum of materials, products, systems, and services, including fuels. Countries often align their standards with either the ASTM protocols used in the United States or the EN (European Norm) standards used by the European Union. She pointed out that alignment between the standards for materials intended to be blended, such as petrol and ethanol, is crucial for consistency and compatibility. For example, ASTM D4806 for ethanol is designed to be compatible with ASTM D4814, the standard for petrol, ensuring proper blending and performance.

“Beyond vehicles, these standards may also need to apply to other spark ignition engines, including motorcycles, lawnmowers, generators, and boats. Countries like Nigeria employ a combination of ASTM and EN specifications to suit their specific requirements, highlighting the flexibility and adaptability of these protocols” she said.

KEY DIFFERENCES AND ENVIRONMENTAL IMPLICATIONS

“While global fuel standards are generally aligned, notable differences exist in parameters such as the concentrations of benzene, aromatics, and olefins—impurities in gasoline that significantly impact emissions. The maximum allowable levels of these substances are often set based on a country’s environmental goals and may also tie into vehicle emission standards.

“The ASTM D4806 standard for ethanol, widely recognized in the industry, includes detailed specifications for ethanol purity and the presence of contaminants like methanol, a byproduct of ethanol production. Critical parameters include limiting solvent-washed gums, which can form deposits that hinder engine performance, and controlling acidity, which relates to ethanol’s corrosivity. Standards also cover workmanship aspects, such as the clarity and cleanliness of the fuel, ensuring the absence of contamination.

PERFORMANCE CHARACTERISTICS OF ETHANOL BLENDS

“Ethanol’s role in enhancing fuel performance is underscored by its higher octane rating compared to gasoline. When blended, ethanol increases the octane level of the resulting fuel, offering better resistance to engine knock. Additionally, ethanol’s purity—lacking sulfur, benzene, and other toxic aromatics—contributes to reduced tailpipe emissions, supporting cleaner combustion and healthier air quality.

“However, ethanol also affects vapor pressure, an important factor in engine starting and vapor lock prevention. Despite ethanol’s lower vapor pressure compared to gasoline, its addition at low concentrations can paradoxically increase the overall vapor pressure of the blend. This counterintuitive effect requires careful management, particularly during warmer months when elevated vapor pressure can exacerbate emissions.

“Another crucial aspect is distillation, which influences smooth engine operation. Ethanol blends are evaluated on parameters such as T50, which measures the temperature at which 50% of the fuel has evaporated, impacting the engine’s response and efficiency.

ETHANOL’S CORROSIVITY AND MITIGATION MEASURES

“While ethanol is inherently corrosive, practical fuel formulations always include corrosion inhibitors to mitigate this risk, ensuring that ethanol does not contribute to increased corrosivity when blended with gasoline. This is a critical consideration for maintaining the longevity and reliability of fuel systems.

NIGERIA’S JOURNEY TOWARD UPDATED FUEL STANDARDS

“In Nigeria, fuel standards continue to evolve in line with regional and international guidelines. Currently, Nigeria adheres to AFRI4 standards under the ECOWAS regulations, with a planned transition to AFRI5 by January 2025. Efforts are underway to assemble a national technical committee for petroleum products, which includes stakeholders such as MEMAN, to review and update these standards in preparation for council approval.

“The adoption of ethanol standards in Nigeria has been a subject of discussion, focusing on the practical challenges of integrating ethanol blends into the national fuel supply chain. While standards for ethanol exist, the ongoing development and alignment with broader regulatory frameworks will be key to successfully implementing these changes.

“As global and national fuel standards continue to evolve, alignment and adaptation remain essential to meet environmental goals, ensure vehicle compatibility, and address the diverse needs of different regions and industries” she said.

Financial Energy Review

Financial Energy Review